Albabond® B Laserschweißdraht

Übersicht

Pd-Basis Aufbrennkeramiklegierung gem. EN ISO 22674, extra hohe Festigkeit, weiß

Vorteile

- geeignet für alle Indikationen der verblendkeramischen Prothetik

- Cu-frei

- gute Verträglichkeit mit Dentalkeramiken durch niedrigen Silbergehalt

- ausgezeichnete Polierbarkeit

- universell verblendbar mit Keramik oder Composites

Specifications

| Product details | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Composition (Content in mass %) |

Pd 74.4 Au 5.3 Ag 6.5 Sn 8.0 In 1.0 Ga 4.5 Ru 0.3 |

|||||||||||||

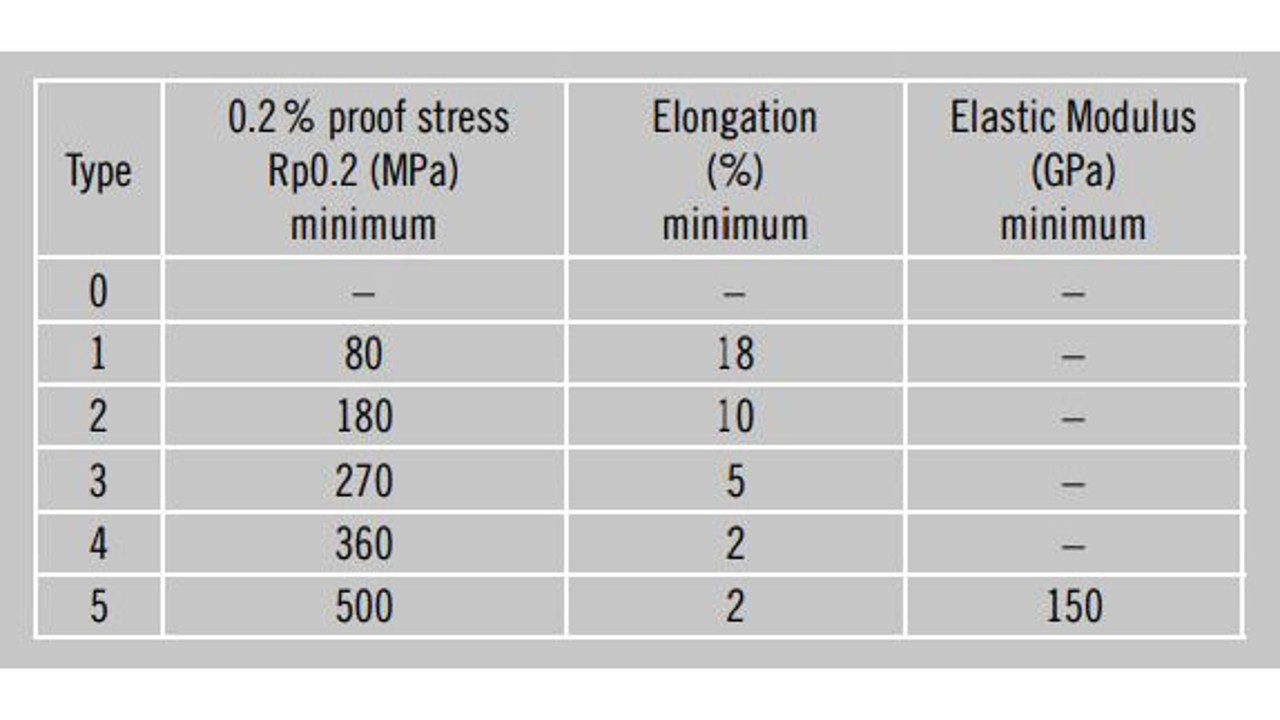

| Type (Classification acc. EN ISO 22674) |

4 (s/v/k) s= self-hardening alloy after slow cooling in the mould v= Condition after hardening k= Bonding alloy: condition after ceramik firing |

|||||||||||||

| Shade | White | |||||||||||||

| Indication |

Crowns Bridges Milling technique Implant restorations |

|||||||||||||

|

Article Code |

1095 0000 | |||||||||||||

| Technical data, melting and casting | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Melting range(1) |

Solidus 1120 °C Liquidus 1300 °C |

|||||||||||||

| Preheating Temperature | 900 °C | |||||||||||||

| Casting Temperature | 1450 °C | |||||||||||||

| Crucible | Ceramic | |||||||||||||

| Density(1) | 11.7 g/cm³ | |||||||||||||

| Hardness, HV5 |

w/k 225 v 240 s 225 |

|||||||||||||

| 0.2% proof stress(1), MPa(2) |

w/k 460 v 470 |

|||||||||||||

| Elongation(1) % |

w/k 41 v 40 |

|||||||||||||

| Elastic modulus (1), GPa(2) | 128 | |||||||||||||

| Ceramic firing | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CTE | 13.5 | |||||||||||||

| Oxide firing |

880°C(1) 10 min vacuum - no |

|||||||||||||

| Soft annealing | --- | |||||||||||||

| Processing after oxide firing | Sandblasting with 125µm Aluminium Oxide | |||||||||||||

|

Cooling after ceramic firing (Relexation cooling is recommended for lang span, bulky frameworks) |

HeraCeram: Rapid cooling At the end of the programm the firing platform is completely and firing tray with objects is removed emediately. The firing tray can cool next to the furnace on a fire-resistant tray. Others: Follow the instructions of the ceramic manufacturer. |

|||||||||||||

| Hardening |

600 °C 15 min. |

|||||||||||||

| Solder/Laser welding wire | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Prior to Ceramic Firing | ||||||||||||||

| Solder | Herador Lot | |||||||||||||

|

Herador 1070 Lot Working temperature °C: 1070 / Solder colour: white |

||||||||||||||

|

Herador 1060 Lot Working temperature °C: 1060 / Solder colour: yellow |

||||||||||||||

|

Herador 1060 S Lot Working temperature °C: 1060 / Solder colour: yellow |

||||||||||||||

| After Ceramic Firing | ||||||||||||||

| Solder | Herador Lot V(1) | |||||||||||||

| Flux** | Work. temp.* 800°C / Solder colour: light yellow | |||||||||||||

| Alloy also available as Laser welding wire | ||||||||||||||

| Ø 0.5 mm x 200 mm | + | |||||||||||||

| Ø 0.3 mm x 200 mm | + | |||||||||||||

Spezifikationslegende

Zusammensetzung:

w = Nach Weichglühen und Abschrecken

k = Verbundlegierung: Zustand nach dem Brennen der Keramik

v = Zustand nach dem Härten

s = Selbsthärtende Legierung, nach langsamem Abkühlen in der Form

Anmerkungen

A = Für langspannige Brücken und Suprakonstruktionen wird ein stabiles Gerüstdesign mit verstärkten Verbindungen und einem Querschnitt von 8–10 mm² benötigt. Zusätzlich müssen die Gerüste gehärtet werden.

B = Abhängig vom Kupfer- und/oder Silbergehalt kann es in einigen Fällen nach kurzer Tragezeit zu Verfärbungen bei Doppelkronen kommen.

C = In Ausnahmefällen können diese Legierungen auch für traditionelle Teleskopkronen mit parallelen Wänden sowie für die Stabguss-Technik verwendet werden, sofern die Querschnitte der Kronenwände, Approximalbereiche, Stäbe und laserverschweißten Verbindungen besonders dick sind und die Legierung anschließend gehärtet wird. Keine Anwendungsempfehlung für konische Kronen und Scherverteiler.

D = Typklassifizierung gemäß EN ISO 22674

Technische Daten, Schmelzen und Gießen:

Kontraindikationen

Bei Überempfindlichkeit (Allergien) gegenüber einem der Bestandteile der Legierung.

Nebenwirkungen

In Einzelfällen wurden Überempfindlichkeitsreaktionen (Allergien) oder elektrochemisch bedingte lokale Missempfindungen berichtet.

Wechselwirkungen mit anderen Dentallegierungen

Bei Approximal- oder Antagonistenkontakt mit Prothesen aus unterschiedlichen Legierungen können galvanische Effekte auftreten. Andere Materialien müssen verwendet werden, wenn der Kontakt mit anderen Legierungen dauerhaft lokal elektrochemisch bedingte Parästhesien verursacht.

Hinweise:

1) Gemäß EN ISO 22674

2) 1 MPa = 1 N/mm², 1 GPa = 1000 N/mm²

3) Bei keramischer Verblendung benötigen diese Legierungen keinen zusätzlichen Härtungsprozess, um ihre maximalen physikalischen Werte zu erreichen.

4) Normalerweise sollte die Vorheiztemperatur 900 °C betragen. Bei Formfüllproblemen mit dünnen Copings wird empfohlen, die Vorheiztemperatur auf 950 °C zu erhöhen.

5) Für Aufbrenntechnik

Keramikbrand:

Hinweise

1) Beim Verblenden mit Keramiken mit höherer Brenntemperatur muss der Oxidbrand bei der höchsten Keramikbrenntemperatur durchgeführt werden; die maximale Temperatur von 950 °C darf nicht überschritten werden.

2) Oxidbrand: Bitte beachten Sie die Anweisungen des Keramikherstellers.

3) Befolgen Sie die Anweisungen des Keramikherstellers.

4) Härtung vor dem Brand (Konditionierung für Frästechniken): 930 °C, 15 Minuten, schnelles Abkühlen.

5) Bei Verblendungen mit Keramiken ist für diese Legierungen kein zusätzlicher Härtungsprozess erforderlich, um ihre maximalen physikalischen Werte zu erreichen.

6) 25 – 500 °C gemäß EN ISO 9693

Lote / Laser-Schweißdrähte:

Hinweise

* Die Arbeitstemperatur ist Teil der Bezeichnung des Lots.

** Empfohlene Flussmittel:

Edelmetall / Edelmetall: geeignetes Flussmittel verwenden

Edelmetall / Nichtedelmetall: geeignetes Flussmittel verwenden

Nichtedelmetall / Nichtedelmetall: geeignetes Flussmittel verwenden

1) Herador Lot V800 muss unter Vakuum gelötet werden. Graphit-Brennträger sollten verwendet werden.

2) Empfohlene Alternativlegierung.

3) Bei Verarbeitung mit HeraCeram.

4) Eine präzise Temperaturkontrolle muss sichergestellt sein. 740 °C dürfen nicht überschritten werden. Maximale Heizrate: 55 °C/min.